TLGC NEW EQUIPMENT FLEET

Investing in hybrid and GPS machinery

12 months ago the main season equipment at The Leicestershire was on its last legs to say the least. With one fairway mower sent to the graveyard and the remaining over 20 years old… things had to change.

The golf club was also spending over £30K per year on repairs and breakdowns. Clearly not sustainable.

We quickly consulted all of the main manufacturers and looked into our options. Early on we decided the club should ideally invest in hybrid technology where possible to help reduce our ever increasing fuel costs.

After exhausting the demonstrations, we were sold on the complete offering by John Deere.

Apart from the 5 deck rotary rough mower, which demands a lot of power, mowers purchased were diesel hybrid. This included two 7500e fairway mowers and four 2750e triples (2 greens + 2 tees).

The jewel of the fleet is the GPS precision sprayer.

Equipment technology

The fleet is fitted with a monitoring system which gathers real time data on equipment performance and productivity. John Deere’s operations centre keeps track of everything… fault codes, machine hours, service intervals, operating hours, even how much fuel is in the machine.

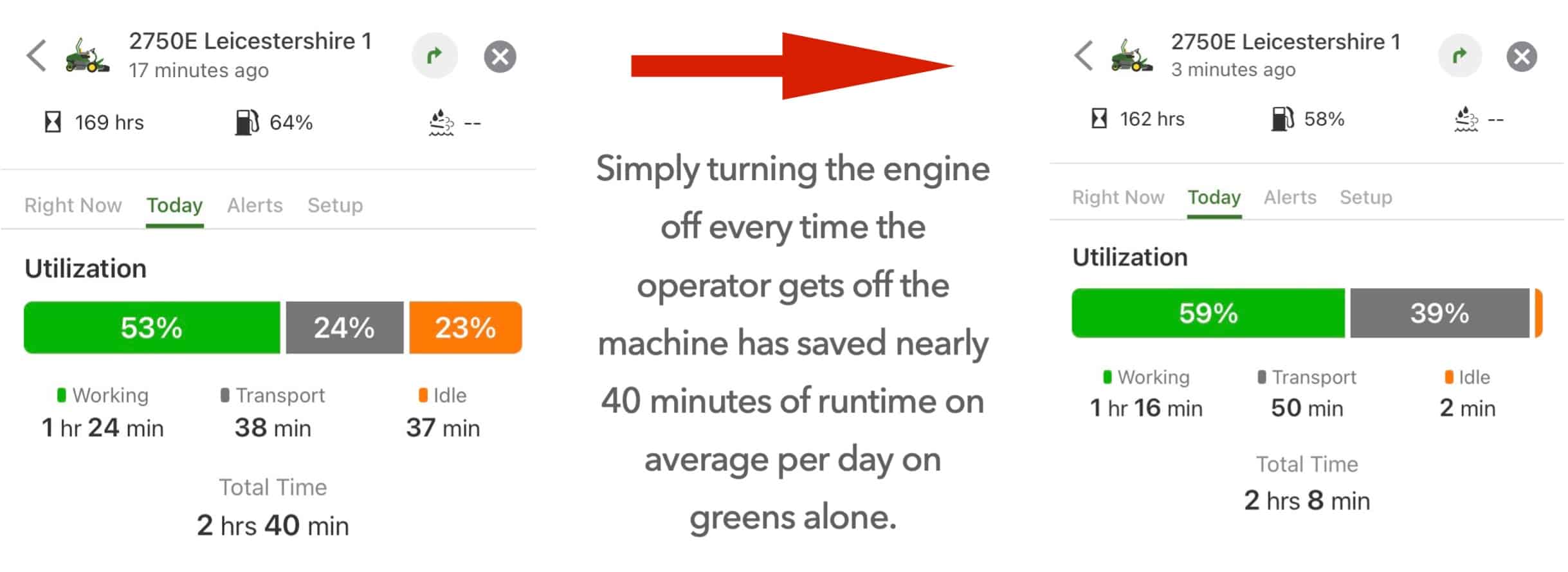

After monitoring our daily usage it became clear the machines were spending a lot of time on ‘idle’, or engine tick over. The reason was simple, each time the operator got off the machine to either take the flag out or switch clippings they left the machine on idle. By simply turning the engine off every time the operator gets off we are saving 40 minutes of engine run time a day on greens alone. Add this up over a year and you have a sizeable amount of fuel being wasted.

The hybrid drive motors on all the cylinder mowers are delivering approximately 20% saving on diesel so far on average depending on reel set up. Greater savings are made when heights of cut are raised during the winter months as the RPM of the reels can be reduced.

The equipment also has pre set cutting and travel speeds to deliver consistency between operators.

GPS Sprayer

The introduction of the GPS sprayer at TLGC has been a massive step forward for both product performance and efficiency.

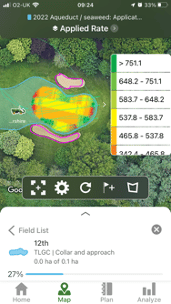

Conventional sprayers have individual boom controls which only allow operators to isolate booms, the sprayers can therefore never spray a circle or curved shape without overspray to make a square pattern.

The GPS sprayer has individual nozzle control which is controlled by the RTK mapping software. The result is complete control over where a chemical is applied and the ability to accurately spray curved areas like greens. We have found a 30% reduction in chemical per area sprayed. For example, the greens were thought to be 1ha, in actual fact they have been mapped at 0.69 ha. When scaled up to areas like fairways (10ha down to 7.2) the savings are considerable.

With more and more chemicals being removed from the market place we feel it is ever more important to ensure every drop of chemical is being applied in the right place. Once a target area is selected using the operations centre, the sprayer is physically unable to spray anywhere else. Once an area has been sprayed, a spray record is generated which includes the products applied, rate applied, operator name, weather, speed applied etc. etc. all of this ensure complete compliance while reducing paperwork. All data can be easily accessed on a smartphone.

Aside from spraying, the mapping software that comes with the sprayer is also useful on its own. We have mapped the entire golf course using the sprayer to accurately measure all features of the course. Pathways have been measured, sprinkler locations flagged, bunker areas quantified. All of these measurements allow accurate ordering of materials and application of products. Areas of ecological importance can also be ring-fenced using the operations centre hub.

The environmental benefits in this case line up exactly with the financial savings. When considering costly products such as wetting agents or fungicides… For us every 4th application is now effectively a free one.